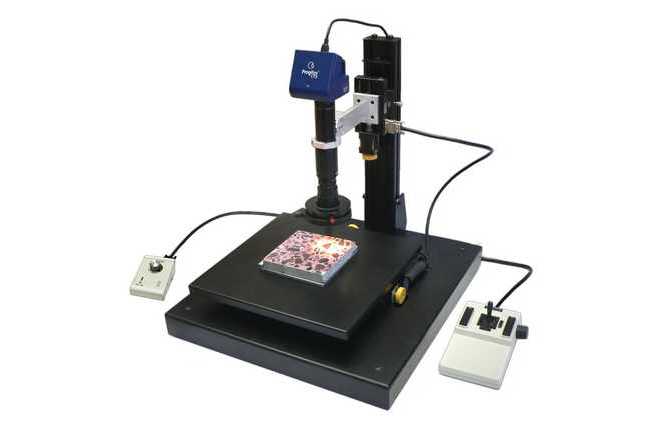

A concrete analysis (also called spacing factor measurement) determines the amount of air voids in concrete samples which is a measure of frost resistance. The software application of NIS-Elements provides the means to perform such an analysis reliably and efficiently. Combined with a motorized scanning stage, the system is fully automated which significantly speeds up the measurement.

The implemented method strictly follows the European Standard EN 480-11:2006 E. Using the traversing method, the amount of air in the micropores is measured on prepared concrete samples. The results are:

-

Histogram of pore size distribution

-

Total traverse length

-

Total air content

-

Total number of traverses measured

-

Specific air content

-

Spacing factor

The method requires 2 samples sized min. 150 x 100 mm with as flat a surface as possible.

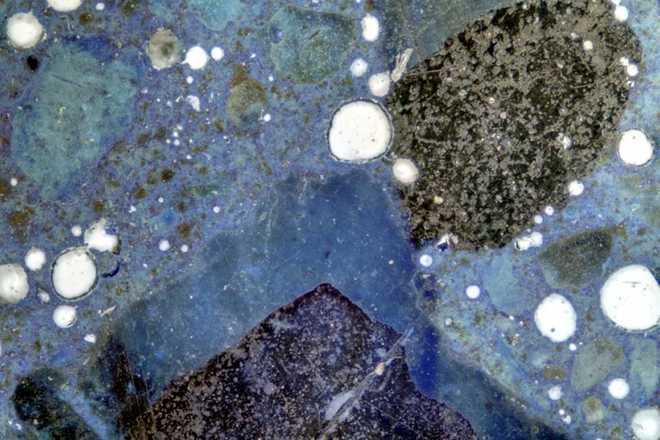

Air voids are filled with a white (zinc) paste while the rest of the material is painted dark - usually with ink - to achieve the highest possible contrast.

The key to successful analysis of air voids is to prepare the sample correctly. The painting, drying, removing of surplus ink and paste have one goal - to achieve an ideal set of white circles with sharp boundaries on a dark background on the whole area of the sample. This all requires a deep experience in sample preparation, a good concrete grinder, a polishing machine and a proper dryer.

Air voids are spatial (3D) objects so the measurement is based on stereological calculations where the input data are lengths of intercepts of air-bubble circles with a set of parallel lines of 2400 mm length in total (as the exact geometry is described in the standard).

While a color camera is preferred generally, there are operators who consider a monochromatic camera to be better. The standard itself does not require any specific camera type.

The EN standard mentions the 100x magnification (10x objective + 10x eyepiece) and a stereo-microscope for the human-eye analysis. However, from the metrological point of view, any microscope or macro-optics with the optical axis perpendicular to the sample surface is significantly better. Both a microscope Nikon LV series or a stereo-microscope can be used.

The required total length of the traverse line along with the 100x magnification (10x objective) lead to hundreds of measurement fields. That is why a motorized XY stage and a motorized auto-focus are both essential for comfortable use.

Note

There is a software option which enables to use a manual XY stage, but we do not recommend it at all.

The time needed to complete one analysis is about 40 minutes (20 min./sample). The main factor affecting the speed is the flatness of the sample - the flatter, the less time is spent on automatic focusing.

Some labs make a comparative measurement using different magnifications. If the results correlate, than the lower magnification is considered sufficient. It speeds-up the analysis because there are less fields to be scanned and faster auto-focus due to the greater depth of focus. It is just important to keep the length of the traverse line 2400 mm.

Although a well-prepared high-contrast sample enables easy detection of air voids, exclusion of intercepts with white areas which are not air voids may sometimes cause an unwanted delay.